Want to Add Your Personal Touch?

Every year, new brands appear in an overcrowded and fiercely competitive landscape. To stand out from the crowd, you should choose distinctive packaging like MIRON, or take it a step further and go for bespoke packaging that is tailored to your product and conveys the value of your brand. Whether you choose custom packaging purely for its design or because you want to add a specific benefit, it is a strategic choice.

In case you are looking for premium and distinctive packaging with the advantages of biophotonic glass, we are the partner for you! Whether you are looking for a fully customized project or just a custom-colored accessory, we are here to assist you.

To ensure a perfect match between your needs and the final packaging, we always start by immersing ourselves in your brand. Figuring out what your brand stands for and what you want to achieve, what opportunities we can seize, and what problems we should address. And last but not least, whether the desired route is feasible or not – this may depend on production volume or required investment. From there, we can help you create something unique that aligns with your brand’s positioning. A packaging that preserves the value of your high-quality product, contributes to the customer experience, and simply stands out - a perfect blend between originality and your brand’s DNA.

Now, before we get into an overly romantic image of creating your bespoke bottle or jar, cap or spray, there are a couple of things to keep in mind. It takes time, it takes true partnership, and it’s more costly than picking items from our standard design range. But, if you got the desire, the stamina, and required volumes to make it cost-effective, then it’s good to know what steps we will be taking together to realize your vision.

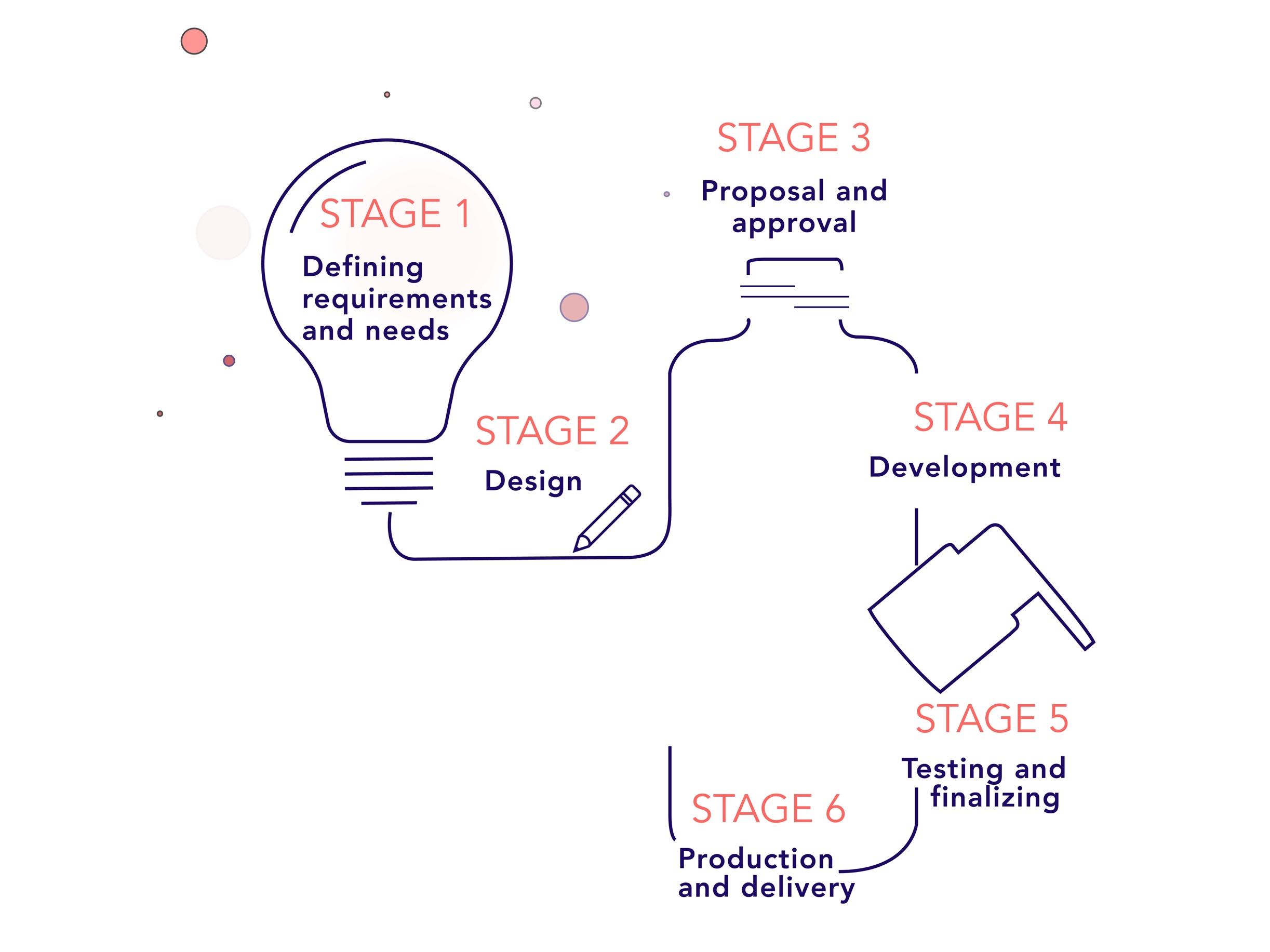

Custom projects are well... custom. So, the duration and exact steps to take will deviate project by project, but we will always go through our six proven stages of developing a new product:

- Define Requirements and Needs

What do you have in mind? What are the must-haves and no-goes? In this phase, all requirements are defined and noted. These include, for example, the type of thread to be used, the usability, and the compatibility of the product with the packaging material. - Design

What is the overall ‘gestalt’, the shape, and the line-up? Does it include sub-ranges? How do we distinguish the different items in the range? Based on your answers to these questions, a first design will be made (custom-route) and discussed. Once we settle for a direction, this design will be refined and ultimately converted into a technical drawing after approval. If you already have a packaging design in mind, we can also work from your drawings. The technical drawing will be developed at a fixed price of 1,000 euros, which can be deducted in the successive phases. In the second half of this phase, a 3D print can be generated so that the first decisions can be facilitated. Also, the accessories (e.g., sprays or lids) need to be accurately portrayed at this time. - Proposal and Approval Stage

So, what do you think? Let’s go for it? Here we ask for your approval of the technical drawing(s), 3D samples, estimated lead time(s), and price/tooling costs, among other things. - Development

Is this what it should be? Can we further refine? We understand that you will want to hold and feel your custom products before proceeding to a full production run. So once the approvals are in, the construction of the tooling and molds can begin. As soon as the trial mold is created, we’ll be able to do a trial run so samples can be sent out for testing and review. - Test & Finalization Stage

It looked good on paper, but will it fly? Do the closures fit perfectly with the bottle/jar? Based on feedback obtained from the pre-production samples in the development stage, the tooling / technical drawing(s) may be modified if necessary. Please note that not all production sites go through this stage; in that case, the first samples can only be obtained from the production run. After we have received your approval on the samples, and upon getting the green light, the complete mold set will be prepared. - Production & Delivery

When will you have your custom items? In this phase, the final production planning will take place. Glass campaigns are planned over different time slots, and depending on the required volumes per item, the run will take 1, 2, 3 days. Once produced, after all required quality checks, we’ll ship them to our warehouse or, should you desire so, directly to your site or filler in order to operationalize the pack and ultimately get it in the hands of your customers.

How Others Experienced It

“As a start-up company, having to invest so much into tooling and the energy involved in creating this custom packaging was quite stressful, but it really paid off. And it was worthwhile.” Joy Isaacs – Founder of ARgENTUM Apothecary

Required Volumes

As you can imagine, developing tooling for bespoke products can be costly, and deploying them also takes time. Therefore, please realize that a minimum order quantity (MOQ) is required to fill an entire production run. Depending on the production line, and the size and shape of the desired packaging, exact quantities can be determined. Generally spoken, the cost of creating a new mold starts at 15,000 euros. For fully customized closures, this can even be more costly. But no worries, we will help you calculate whether it’s economically viable or not and advise you on the options out there.

Semi-customized Accessories

When it comes to small brand-specific accents (such as colors, decoration, etc.), volumes are available from as little as 10,000 pieces - depending on the type and supplier. Not only are the MOQs of these semi-customized accessories lower, but the lead times involved are also much faster; they often vary between three and six months.

Timeline

How long will it take? Well, it depends, of course. Especially for the desire and design stages, it is not easy to give a set timeline, as every project is different in nature and complexity. The project can go back and forth in the early stages until the perfect design has taken shape. If you are looking to launch a new product soon, we strongly recommend that you reconsider our existing design range. However, if you have time to develop something bespoke and everything goes according to plan, we can deliver your beautiful custom packaging within 9-12 months.

How Can MIRON Be of Help?

We acknowledge the importance of creating something distinctive, and we can help you achieve this through our creative team that helps you turn ideas into reality. With our market-leading expertise in biophotonic packaging and our ability to recommend technical solutions, we can offer a total packaging solution.

Interested in discussing your packaging project? There are so many options to consider, among others:

- Tool design.

- 3D print files for a packaging design.

- Exploring the financing possibilities (e.g., full- or partial ownership).

- Fully customized products or personalized elements.

- Partners for the decorating process – printing and labeling.

Our sales team would be happy to go over the various options with you in more detail.

GET IN TOUCH